Designing for railroad noise control is all about low frequencies. Standard noise control reference information is of very little use. We had to go “off label”, as the doctors say. We had noise source data and our in-room noise goals. We dug in and drafted noise control performance specs for insertion into all elements of the building shell, including structural, masonry, curtain wall, roofing, HVAC, exterior doors, glazing, insulation, sound control isolation clips, interior wallboard, caulking, etc. At Jim’s direction, we did not specify any specific product or manufacturer, but requested that the design-build contractor evaluate the noise control benefit vs. cost of every viable design and material option. These options were then reviewed on spreadsheets by the project team, with additional consideration of installation labor costs, availability, etc. Final design strategies were decided, and product selections were made for each material item. We followed the same procedure concerning interior wall designs and the selection of materials.

We worked closely with the project architects to integrate the materials into design-build documents, and then coordinated construction with the design-build contractor and the owner’s construction manager. We reviewed shop drawings. We required lab sound performance tests of the pre-selected curtain wall panels with glazing units installed, prior to fabrication of all panels. The first test failed, primarily due to a 5 dB deficiency in one of the 8 frequency bands tested. The Owner determined ” We have Richard’s noise control performance requirements, and we will stick to them.” Exterior construction was halted. An upgraded curtain wall and glazing unit was fabricated, increasing the overall thickness by 1/2″. The curtain wall system and glazing was retested and passed. A custom fabrication order was placed. Exterior building construction resumed 3 months later, and as a consequence, the Hotel opening was delayed 3 months. (I have great respect for an owner that sticks to his guns through design, funding, and construction, enduring short-term adverse consequences to achieve long-term benefits)I visited the jobsite and observed construction in progress as the first floor was being constructed. I identified several minor issues concerning installation of the exterior curtain wall, and construction of the exterior and interior guest room walls, and these issues were quickly corrected.

The Project Team worked through countless issues with the Owner throughout the project, from concept through completion.I really appreciate having had the pleasure of working on this project with Jim and his wife, Rebecca, President of Riverview Hotel Development. They firmly set primary design goals (e.g., no train noise in the guest rooms) way before a spade of dirt was turned.Another primary design goal mandated no guest should hear the TV from the adjacent Guest Room, despite the fact that their design required that TVs would be wall-mounted. The project is a legacy to Rebecca’s family heritage of Hotel ownership in Muscatine – they owned and formerly operated Hotel Muscatine (now closed) located on the lot next door, for decades, and they now occupy a suite on the 6th floor of the new hotel.

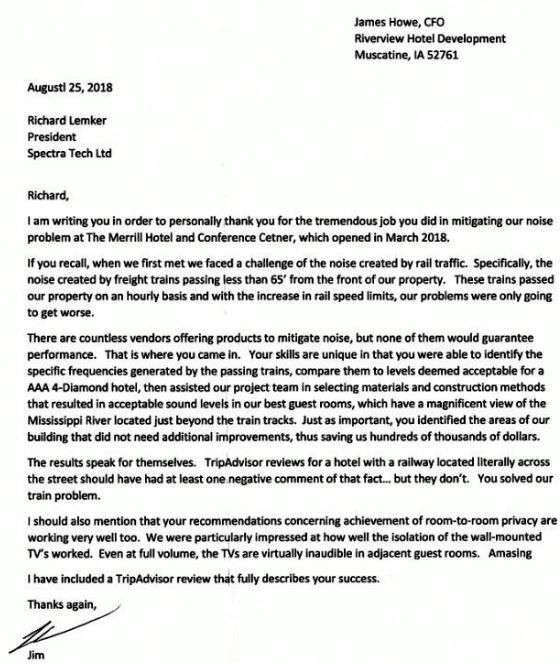

I have recently received a testimonial letter (attached) from Jim Howe. He also sent along Trip Advisor guest comments that in fact compliment the Hotel in regard to the trains, and the Hotel’s excellent overall noise control! See attached. Jim pointed out to me in a recent phone conversation that he cannot believe that after months of operation, he has not seen one NEGATIVE Trip Advisor report mention trains or TV noise. He thinks that is absolutely unbelievable, given the circumstances.