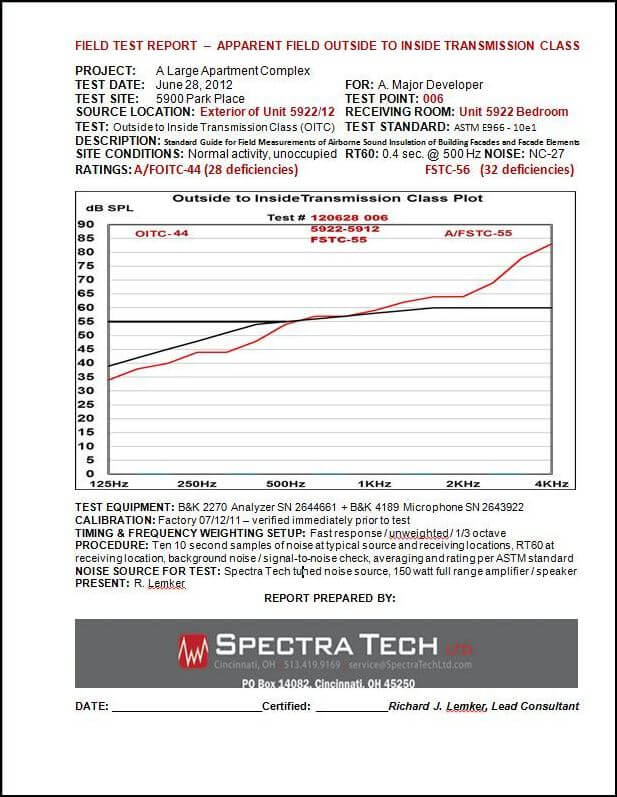

Spectra Tech employes sophisticated equipment and software to automatically measure and document the Outside to Inside Transmission Class (OITC) values of building exterior elements of construction, including walls, doors, windows, and glass curtain walls. We can also provide assistance in designing solutions to increase the sound isolation provided by these elements of construction.

- The Outdoor-Indoor Transmission Class (OITC) assigns a single number rating to measured sound Transmission Loss (TL) data obtained in accordance with ASTM E90. The OITC is defined as the A-weighted sound level reduction of a test specimen in the presence of an idealized mixture of transportation noises: aircraft takeoff, freeway and railroad pass by. The rating is computed from the measured TL data in one-third octave bands from 80 Hz to 4000 Hz, inclusive.

Spectra Tech Ltd, OITC data logging computer system, on-site field test - This is the “field” version of testing normally done by product manufacturers to rate the Outside to Inside Transmission Class (OITC) performance of a product or material when tested in an ideal laboratory setting. OITC performance values are nearly impossible to obtain in the field, due to inherent deficiencies associated with field construction.

- To test the transmission of sound through a particular building exterior element of construction, a broadband spectrum of noise is generated outside of the building at all frequencies between 63 Hz and 8,000 Hz and amplified to provide a level at the receiving side (inside the building) that is sufficiently higher than the receiving room’s normal ambient noise level.

- The average unweighted (fast response) sound levels for each octave frequency band between 80 Hz and 4,000 Hz (4KHz) is recorded at ten random locations on the “source side” of the construction for a period of 10 seconds or more.

- Then, the average unweighted (fast response) sound levels for each octave frequency band between 80 Hz and 4,000 Hz (4KHz) is recorded at ten random locations on the “receiving side” of the construction for a period of 10 seconds or more.

- A reverberation time test is also conducted in the “receiving room” and if the room reverberation is not found to be within the nornal criteria, adjustments to the OITC rating must be made accordingly.

- To compute the OITC, the measured specimen TL, for each one-third octave band, is subtracted from the A-weighted Reference Transportation Noise levels. A logarithmic summation of the one-third octave band TL is performed. The OITC is the difference, rounded to the nearest decibel, between the value 100.13 and the logarithmic sum of the one-third octave band TLs.

- Plot / Print Test Results: We get the results instantly – in the field. We can provide documentation of test results by plotting / printing the test values on paper, and / or provide the reslts in PDF format.

So you have tested your door, wall, or window and it doesn’t meet the project’s OITC criteria – – – – Now what?

We do more than simply give you test results. We can help you raise the OITC rating!

- FOR DOORS: Most often, door OITC performance deficiencies can be traced to the door’s seals. It is likely that there will be no visible or measurable gaps around the perimeter of the door at the seals. We can immediately perform a proprietary “sniff test” (developed by Spectra Tech’s staff for use in our government security testing) to locate the exact point(s) of sound leakage. Within minutes, it is likely that your staff can make necessary adjustments to the door’s seals per our specific instructions. The door can be retested. Sometimes, a few adjustments must be made, but eventually the door OITC value will increase until the targeted OITC rating is obtained.

- FOR WALLS: Deficient wall performance can often be traced to field construction deficiencies. We can immediately perform a proprietary “sniff test” (developed by Spectra Tech’s staff for use in our government security testing) to locate the exact point(s) of sound leakage through the wall. Our sniffer can even locate deficiencies such as inadequate caulking of drywall – even when these deficiencies are concealed behind a finished baseboard trim strip. Within minutes, it is likely that your staff can install additional caulking and the wall can be re-tested and shown to be in conformance with the project criteria. When the problem is determined to be the result of penetrations that are not readily accessible, or when the overall sound isolation of the base construction is found to be inadequate, we can assist in developing solutions that can be implemented prior to a re-test.

- FOR GLASS WINDOWS: We can often trace the sound isolation deficiencies to frames and gaskets that have not been properly sealed. Within minutes, it is likely that your staff can install additional caulking in accessible openings, and the location can be re-tested. When the problem is determined to be the result of installation elements that are not readily accessible, or when the overall sound isolation of the base construction is found to be inadequate, we can assist in developing solutions that can be implemented prior to a re-test.

For a comprehensive list of acoustical measurement variables and criteria that can be measured and / or computed, please visit Detailed Measurement Specifications & Definitions

For specifications on our primary audio test equipment, please visit Audio Test System Specifications

- ACOUSTIC PRIVACY, SPEECH INTELLIGIBILITY, AUDIO SECURITY, Office, Education, Residential, Spectra Tech Ltd, Consultant

- Silent Guard Virtual Sound Lab – demonstrates the sound isolation for windows with various STC /OITC ratings using several exterior noise sources (link at Silent Guard website)

- Onsite, On-site, Speech Privacy, Privacy, Testing, Sensitive Compartmented Information Facility, SCIF, Proves Its Value, Spectra Tech Ltd, Consultant

- Guide, Speech, Privacy, Test, Printout, Spectra Tech Ltd, Consultant